Honeycarb coal activated carbon is made from a series of processes, such as carbonization, cooling, activation and washing. Its appearance is generally black cylindrical activated carbon, amorphous coal particle activated carbon, powder activated carbon. The cylindrical activated carbon is also known as columnar charcoal, which is usually made from powder raw materials and binder by mixing and extruding and then carbonization and activation. It has developed pore structure.

Type D coal pillar activated carbon:

Widely used in solvent recovery, industrial waste gas purification, protective equipment, domestic air purification, power plant raw water purification, purified water treatment, power plant raw water treatment,

The water treatment of the electronic factory, the water treatment of chemical pigments, the water treatment of the food factory and the pharmaceutical factory, and the waste gas treatment of the biological carriers, factories and garbage sites of the sewage plant,

It can be used for water reuse, seawater cultivation, and other aspects. It can also be made in pure water, sewage treatment, sewage biological carrier, seawater cultivation, and cold storage and factory space.

Gas purification and other fields.

B type raw coal crushing particle activated carbon:

It is suitable for the application of raw water purification in power plant, especially in the filtration and purification treatment of chemical wastewater, and the treatment of chlorophyll with bitter salt water in power plant boiler.

Processing effect. And the soil improvement of golf course.

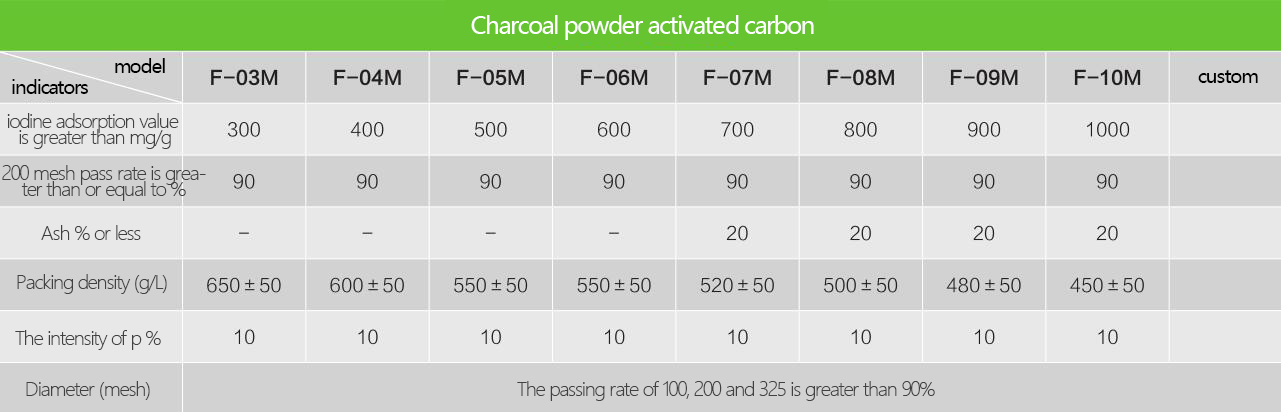

M-type coal powdered activated carbon:

It is mainly applicable to water purification, which can absorb organic matter, residual chlorine and odor in raw water, reduce turbidity and improve taste, so as to meet the standard of drinking water.

The product also has good treatment effect in the sewage treatment industry.

[inspection standard] GB/T 7702-1997, GB/T 7720-2008, qys01-2013.

Packaging: plastic woven bags of 25kg or 500kg each.

[remarks] no project quality indicators can be produced according to customers' requirements.